products

Products & Services

AC Motor Drive - Inverter

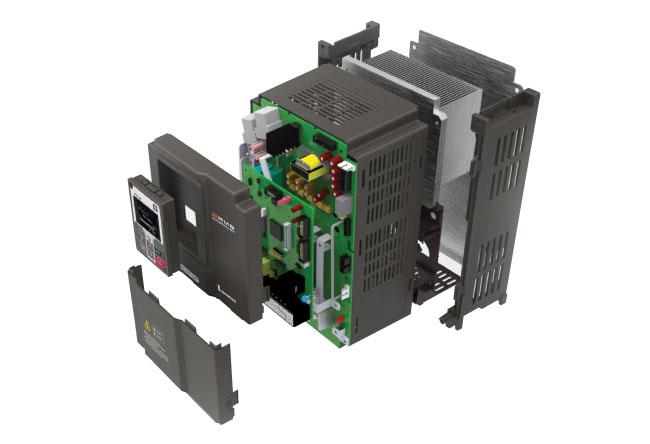

RM6G1 RM6G1e Series Inverter

ID’╝ÜRM6G1/RM6G1e

The inverter of product line has been fully evolved to meet the latest motor control trends. The new generation RM6G1 multifunction vector control inverter with non-sensor/ with sensor vector control mode, supports high performance speed control and torque control like IM, IPM and SPM motors, which can be applied to speed control, torque control, tension control, position control and various light and heavy load industrial equipment. With RM6A6 power regenerative unit replacing the brake resistor, it can send the motorŌĆÖs regenerative energy back to the power grid, solve the heat dissipation problem of the brake resistor and meet the requirement of energy saving at the same time.

The capacity range of RM6G1 series inverter is 0.4kW ~ 500kW.It has excellent operating capability and stability, and strong overload capability, providing customers with a good operating experience in various light and heavy load applications.

The capacity range of RM6G1 series inverter is 0.4kW ~ 500kW.It has excellent operating capability and stability, and strong overload capability, providing customers with a good operating experience in various light and heavy load applications.

Products InfoInformation

Control Features

High Stability Speed Accuracy

The speed stability error can be less than 0.05%, which can meet the requirements of high accuracy in automatic storage, textile, metal sawing, and servo injection machines.

High Torque Output

The non-sensor vector control technology enables the motor to reach 200% of the rated torque at very low speed, which is suitable for high starting torque and heavy load operation, such as ground improvement machine, tunnel boring machine, air compressor, drilling machine, elevator and overhead crane, etc.

High Response Speed

The motor speed decreases when the load is applied. The high response capability enables the motor to return to the set speed within a short period of time, which is suitable for punching machines, air compressors, metal saws and servo-hydraulic machines.

High Speed Output

The high speed control capability of the inverter can be applied to the high speed spindle of machine tools, optical grinding machines and magnetic bearing centrifugal compressors. The RM6G1 standard model can operate at a maximum of 600Hz and the high-speed control model can reach 2000Hz.

Applications

Compressor, crane machine tool, elevator, conveyor, fan, extruder, winding machine, stamping machine, textile machine, pump and blowing machine, etc.

Application Functions

- The speed feedback card can be selected according to the codec type and supports Line Driver, Push-Pull, Open Collector and Resolver.

- PID control with auto-sleep and wake-up functions for pressure and temperature control applications. PID function can also be opened independently for other devices.

- Supports high-speed pulse input/output control applications.

- With regenerative avoidance function, it can reduce energy consumption and save the cost of brake transistor and resistance.

- Can be paired with KP-602 full-color LCD display keypad with multi-language support.SPEC key can set the analog digital input terminal function, 60 functions such as forward/reverse, primary and secondary frequency, secondary acceleration/deceleration, etc.

- 2 sets of independent motor parameters can be established, and a single inverter can switch and control two different motor specifications.

- Kinetic Energy Backup function for power failure compensation and deceleration stop.

- Traverse control for textile applications and tow(fiber) conversion control.

- Built-in RS-485 Modbus communication interface, and option card can be added to increase the communication interface.

Safety Function & Prediction and Maintenance

Safety Function

- With the STO safety torque off function to build a high safety system. Safety switch output terminal is also provided for system linkage protection.

- Complete safety protection functions such as stall prevention, overvoltage suppression, high excitation braking, high slip braking, and dynamic brake duty modulation are provided to ensure the safety of inverter operation.

Prediction and Maintenance

- Built-in overheat prediction and maintenance function, according to the set temperature value for overheat prediction or protection, to reduce the loss of equipment tripping, support PTC/NTC/PT100/RTD392/KTY84 and other temperature sensors.

- When replacing the fan for models over 20kg, the whole inverter does not need to be disassembled, so it is easier for maintenance and fan replacement.