Energy Saving Solution for Power Regeneration System

Energy Saving Solution for Power Regeneration System

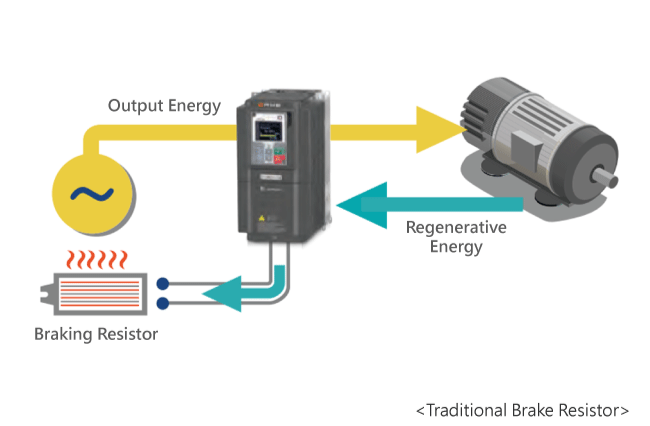

When the motor is in generator mode, the electrical energy will be recharged to the inverter, causing the DC side voltage to rise continuously. The traditional method requires the installation of braking resistors on the inverter, using the on-resistance to consume excess electrical energy to keep the DC side voltage of the inverter stable. In order to balance the voltage, the resistor is used to convert the power generated by kinetic energy into heat energy, which is an invisible waste of power.

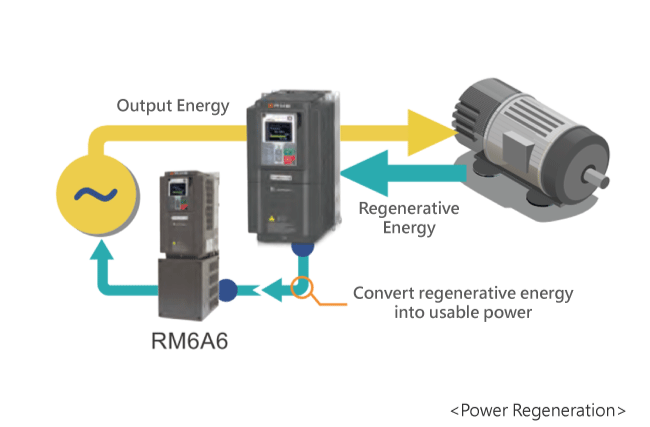

Inverter paired with Power Regenerative Unit RM6A6 can not only replace the traditional braking resistors function, but also feedback regenerative energy to the grid. The power feedback efficiency can reach 95%, and it has double advantages of small amount of heat loss and small size (for high regeneration rate applications).

Applicable machines: Large inertia load, four-quadrant load, fast braking, long time energy feedback, such as textile drafting, gantry-type processing machine, elevator lifting equipment, punching machine, automatic storage, etc.

Motor Power Regeneration Principle

Motor, also known as electric motor, is a device that converts electrical energy into mechanical energy. It uses coils to generate a rotating magnetic field that acts on the rotor to produce torque and make the rotor rotate. However, when the actual rotation speed of the motor is greater than the synchronous rotation speed, the motor will turn into an electrical generator, converting mechanical energy into electrical energy and sending the electrical energy back to the power supply. This phenomenon of electrical energy regeneration is commonly found in equipment that requires rapid deceleration or inertia loading, such as elevators, cranes, automatic storage, drafting or winding machinery and equipment.

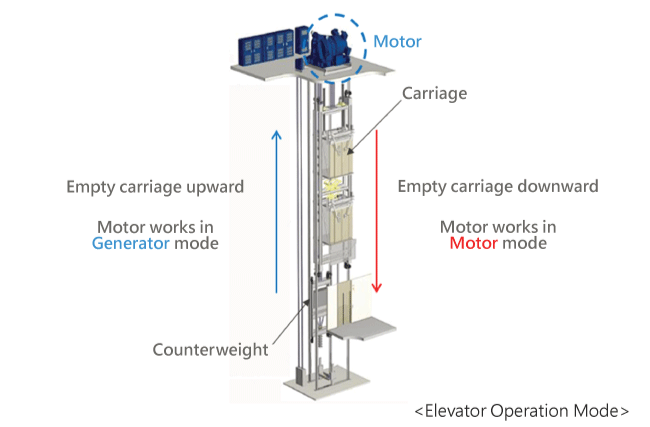

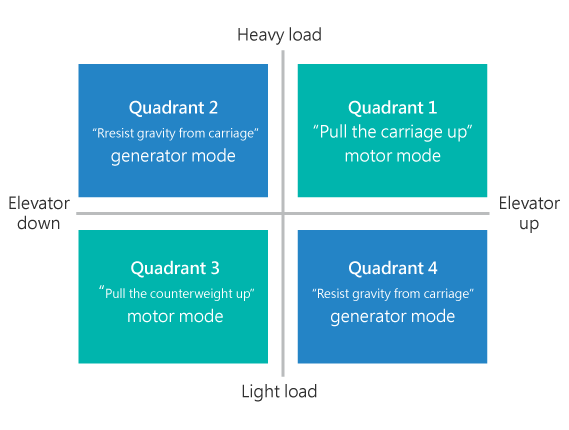

Elevator Regeneration Principle

The elevator structure is designed with counterweight blocks, and most of the usage is light load. The direction of the carriage going up and down can be roughly divided into two categories: When going up, the motor works in motor mode. When going down, the motor works in generator mode.

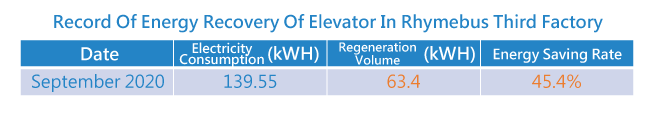

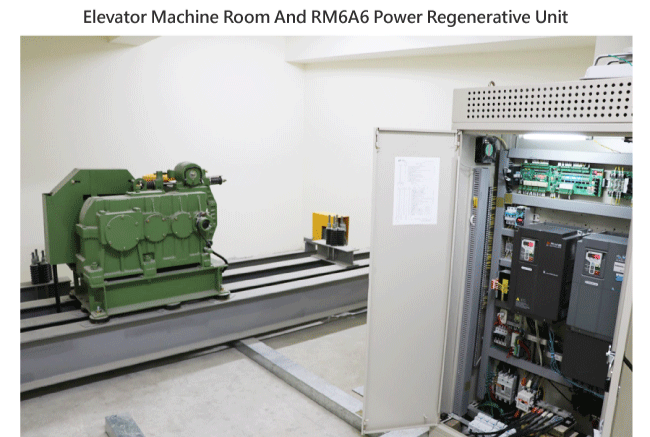

Practical Case of Elevator Application

The maximum load of the freight elevator in the Rhymebus Third Factory is 3000kG, and the height of the building is 8 floors (2 underground floors and 6 upper ground floors), and the rated capacity of the motor is 40HP.

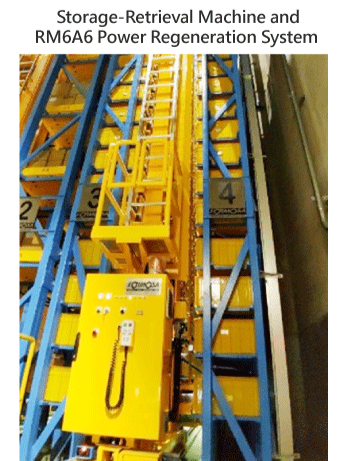

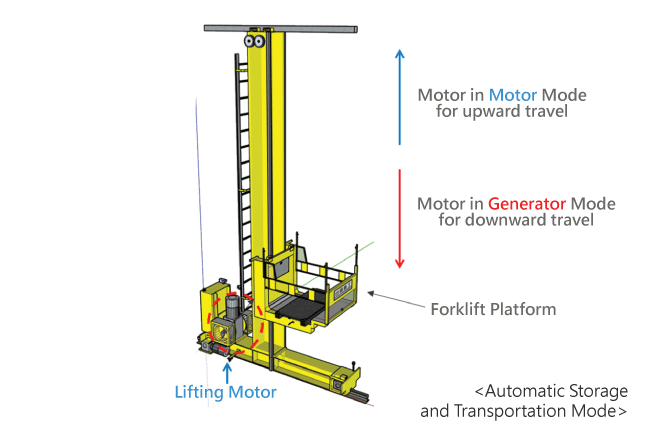

Automatic Storage System Principle of Regeneration

The mechanical operation of the automatic storage is similar to that of the elevator. However, the automatic storage does not have a counterweight block design, so the running direction of the motor electric energy return is exactly opposite to that of the elevator.

When the fork platform of the automatic storage goes up, the motor works in the motor mode; when it goes down, the motor works in the generator mode. The heavier cargo the fork platform carries, the more energy the motor regenerates.

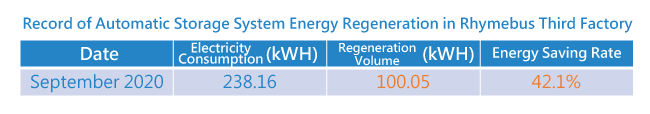

Practical Case of Automatic Storage Application

The maximum load of the automatic storage system in Rhymebus Third Factory is 650kG, the building is 6 floors (2 underground floors and 6 upper ground floors), and the rated capacity of the motor is 20HP.